Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

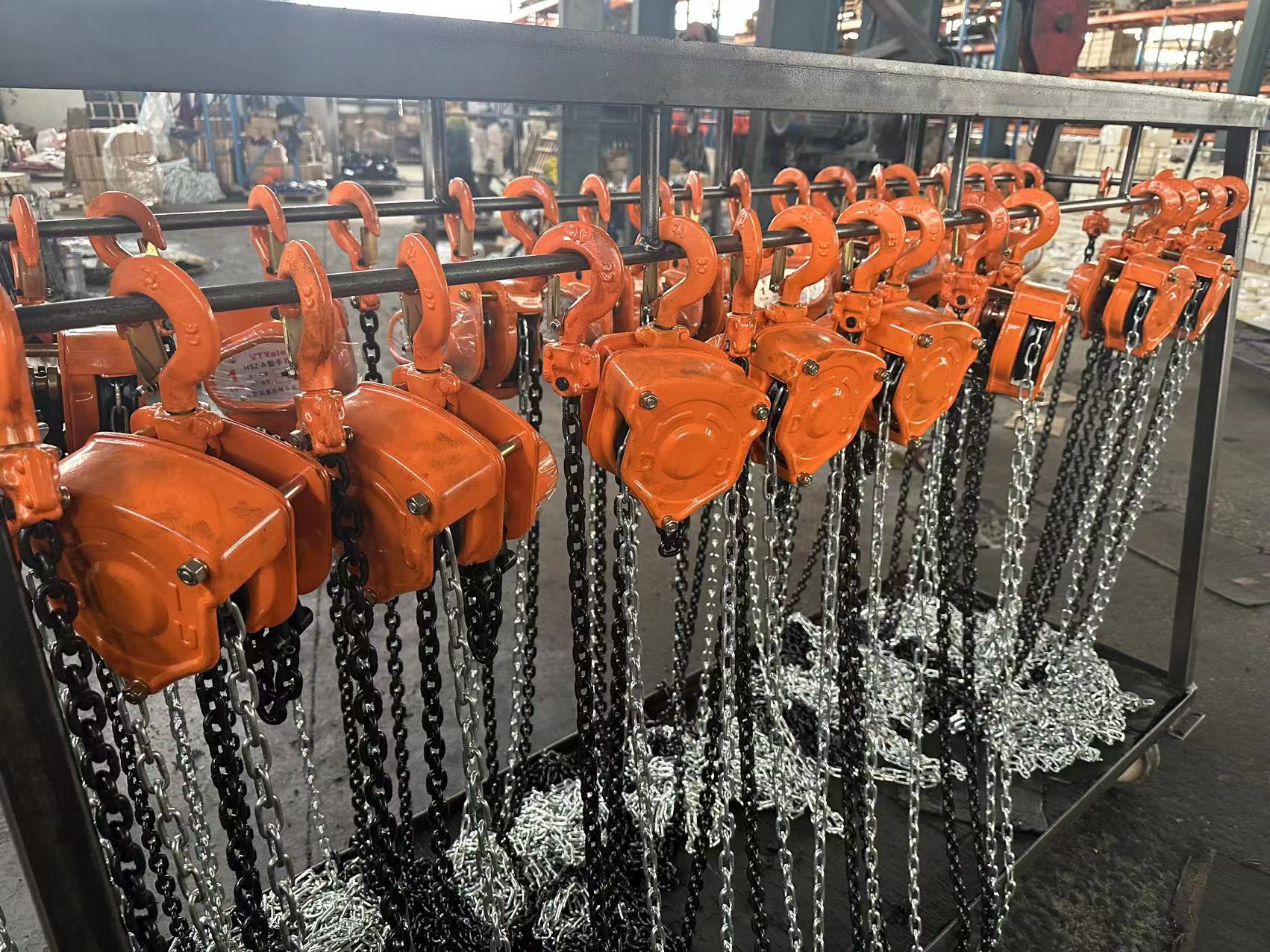

Chain hoists simplify the lifting of heavy objects, yet users commonly experience stiff chains or abrupt resistance. Routine maintenance removes these problems and averts accidents. In this article, we discuss why hoists are difficult to operate and provide useful advice on how to maintain them properly.

Dust, water, or metal shavings clog the chain links and gears.

Friction increases with no oiling, leading to stiffness.

Overloaded hooks or bent chains cause uneven tension.

Improper storage bends internal gears, adding resistance.

Task | Frequency | Tools Needed |

Clean chain with brush | Weekly | Stiff brush |

Lubricate gears & links | Monthly | Industrial oil |

Inspect hooks for cracks | Quarterly | Magnifying glass |

Check load limiter | Annually | Calibration tool |

–Wipe the chain with a dry cloth and brush away dirt.

–Blow debris off gears using compressed air.

–Oil chain links and gear teeth for lubrication.

–Avoid excessive lubrication to avert dust adhesion.

–Replace hooks with visible cracks or stretching.

–Verify the load limiter at 125% WLL.

Neglecting care results in:

•Safety Risks: Snapped chains or broken hooks are injury hazards.

•Higher Costs: Maintenance is 3 times more expensive than preventive maintenance.

•Downtime: 78% of hoist failures are due to inadequate maintenance.

Chain hoists must be regularly serviced to run smoothly and safely. Lubricate and clean parts each month, replace worn parts as soon as possible, and regularly inspect safety devices. A well-serviced hoist will last longer, save you money, and keep your crew safe. Begin your maintenance habit today!

Click on the image below to learn more about the product. →